Aim

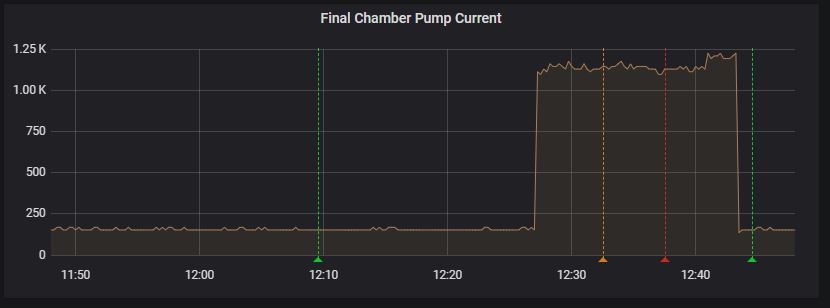

The aim of the project is to provide visibility of when the pump from the outflow chamber of a septic system is operating. Then if it is running for too long we want to be sent an alert to notify us as this is a potential indicator of a problem (blockage leading to overflow).

Method

The method that we will use to achieve this will be to measure the current flowing to the pump and to make that data available to a Prometheus / Grafana instance that will then be used for visibility / alerting.

Requirements

- This project will be leveraging an already installed instance of Prometheus / Grafana.

- An established WiFi network for connectivity.

- Access to some soldering equipment

Materials

- Current Sensor: An ACS712 based module. We'll use a 5A unit since the pump is not expected to exceed 500W.

- Analog to Digital Converter: The ADS1015 will be more than sufficient for our needs.

- Enclosures: The current sensor must be protected to prevent contact with the live terminals. The A2D converter should be protected where possible.

- Voltage divider: We will use three 1k Ohm resistors.

- Wiring: Hook up wires with female Dupont connectors and appropriate wiring for the load connection (I used 2.5mm cabling)

- Compute: Raspberry Pi Zero W with case, micro SD Card, case and headers.

Description

This project is one that has been born out of necessity. Our septic system is a good unit that operates as required however, there have been a few occasions where we have had the outflow from the final chamber blocked for one reason or another (and there have been a variation here). The end result of this has been the increase in water level in the final chamber. In two cases this has not been caught in spite of the inbuilt alarm (that uses a float switch and an annunciator in the garage) resulting in the septic system flooding (not good).

To add some redundancy to the system and to provide remote alerting capability I decided to add my own alerting system.

I considered a couple of different options including;

- Looking at the outflow from the septic tank and measuring the volume of water pumped. While possible, this option involves moving parts in a portion of the system that is space constrained and the method for alerting would involve determining the absence of a thing over a period of time that would be indeterminate.

- An additional (but different) float switch in the final chamber. This was practical and do-able, but the environment is fairly harsh (water, humidity, 'stuff') and it would have been an alert that occurs later in the process of failure (similar to the default installed alarm which once had its float get stuck and failed to alert properly)

- Current sensing for the pump operation. This has the advantage of providing very quick feedback if there is a problem and keeps any measurement in a 'cleaner' space. The down side is that this does mean connecting a sensor to a high voltage part of an electrical circuit and therefore requires doing the work within local regulations and taking the appropriate safety precautions.

I opted for the current sensing option since it was the best of the three options in terms of getting a good result (early detection). I have the advantage of being a registered electrical service technician and therefore am able to do the work safely and appropriately.

Equipment

The current sensor we will use is based on the ACS712 Module. I sourced mine from Banggood, but they are widely available for low cost. This specific one used here is the ACS712ELC-05B which can measure plus or minus 5 Amps corresponding to an analog output of 185 mV/A. The unit is powered from a 5V supply, so we will be connecting it to a 5V output from the Pi and using a voltage divider to reduce the voltage output appropriately for input to the analog to digital converter

If you have access to a 3d printer, you can print an enclosure from the design here.

To enable the current sensing option we will also need to include a digital to analog converter. This should be a fairly simple task similar to the method used here for measuring levels from a gas sensor.

If you have access to a 3d printer, you can print an enclosure for the D2A converter from the design here.

The connection layout is as below (again very similar to the method here);

Operating System Setup

The installation below was carried out using the Raspbian 'Buster' OS. This is available from the Raspberry Pi website.

Install the OS onto an SD card and power up the Pi.

The first thing we should do is to configure the Pi appropriately for use. Some of the steps may or may not be needed depending on your circumstances (i.e. will you be using a model Pi with a physical Ethernet connection or Wifi). Where in doubt check out one of the Raspberry Pi Computing books which will walk through the options.

We can start by running the command;

sudo raspi-config

This will give us access to the options for localisation (WiFi country, time-zone, locale) but most importantly (in this case) for enabling the I2C protocol.

Since the ADS1015 uses the I2C protocol to communicate, we need to load the appropriate kernel support modules onto the Raspberry Pi to allow this to happen.

Since we are using the Raspbian distribution there is a simple method to start the process of configuring the Pi to use the I2C protocol.

On the first page select the Interfacing Options with the arrow keys and then tab to select

Then we select the I2C option for automatic loading of the kernel module;

Would we like the ARM I2C interface to be enabled? Yes we would;

Press 'OK' to acknowledge that the interface is enabled.

Press tab to select 'Finish'.

Once this is done we should do what we should always do when embarking on a fresh install on a Raspberry Pi and that's to update and upgrade the software.

sudo apt-get update

sudo apt-get upgrade

From here, you should look to configuring a static IP address or a WiFi connection if desired. Again, where in doubt check out one of the Raspberry Pi Computing books for options.

sudo raspi-config

sudo apt-get update

sudo apt-get upgrade

Software Setup

There's still some work to do to get things sorted, especially for the I2C functionality. We need to check the /etc/modules file using:

sudo nano /etc/modules

Where we need to ensure that the following line is at the end of the file:

i2c-dev

Under some circumstances (depending on the kernel version we are using) we would also need to update the /boot/config.txt file. We can do this using;

sudo nano /boot/config.txt

Make sure that the following line is uncommented (the '#' is removed from in front of the line) in the file;

dtparam=i2c_arm=on

Then we should load tools for working with I2C devices using the following command;

sudo apt-get install i2c-tools

... and now we should reboot to load the 'config.txt' file if we changed it earlier

sudo reboot

We can now check to see if our sensor is working using;

sudo i2cdetect -y 1

If we were using an older B model of Raspberry Pi with 256MB of RAM, we would need to use sudo i2cdetect -y 0.

The output should look something like;

pi@raspberrypi ~ $ sudo i2cdetect -y 1

0 1 2 3 4 5 6 7 8 9 a b c d e f

00: -- -- -- -- -- -- -- -- -- -- -- -- --

10: -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --

20: -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --

30: -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --

40: -- -- -- -- -- -- -- -- 48 -- -- -- -- -- -- --

50: -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --

60: -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --

70: -- -- -- -- -- -- -- --

This shows us that we have detected our ADS1015 on address '48' (The ADS1015 can support four different addresses as shown on page 17 of the data sheet).

Now we want to install the Python libraries designed to read the values from the ADS1015. The library we are going to use was designed specifically to work with the Adafruit ADS1015/ADS1115 ADCs. In carrying out this library development, Adafruit have invested a considerable amount of time and resources. In return please consider supporting Adafruit and open-source hardware by purchasing products from Adafruit!

We need to change our default version of Python running on the Pi to Python 3

We can check what version is running by executing the following command;

python --version

If that indicates python 2.x, then we need to change that.

To find out what version of Python 3 is available, run the following

ls /usr/bin/python*

Hopefully you will see a 3.x version.

To change the default python version system-wide we can use the update-alternatives command. First list all available python alternatives;

update-alternatives --list python

There is a good chance that the output will be something like;

update-alternatives: error: no alternatives for python

The above error message means that no python alternatives have been recognised by the update-alternatives command. For this reason we need to update our alternatives table and include both python 2 and 3. Just check that the numbers for the versions in the commands below match the versions that the previous command indicated were installed.

sudo update-alternatives --install /usr/bin/python python /usr/bin/python2.7 1

sudo update-alternatives --install /usr/bin/python python /usr/bin/python3.7 2

The last number on each of the previous lines is the priority, with the higher number being the

highest priority

We can check again by running;

python --version

Now the default version should be Python 3

Install pip3 (for Python 3)

sudo apt-get install python3-pip

Then install setuptools via pip

sudo pip3 install --upgrade setuptools

Install python libraries

pip3 install RPI.GPIO adafruit-blinka

Install the ADC libraries (Note: I occasionally get errors when carrying out the following command and need to re-run it a few times);

sudo pip3 install adafruit-circuitpython-ads1x15

We should now be able to run a simple program to test our sensor.

Create a file called current.py (using nano) with the following contents in the home directory (this code can be downloaded from GitHub here);

#!/usr/bin/python

#encoding:utf-8

import time

import board

import busio

import adafruit_ads1x15.ads1015 as ADS

from adafruit_ads1x15.analog_in import AnalogIn

# Create the I2C bus

i2c = busio.I2C(board.SCL, board.SDA)

# Create the ADC object using the I2C bus

ads = ADS.ADS1015(i2c)

ads.gain = 1

# Create single-ended input on channel 0

chan = AnalogIn(ads, ADS.P0)

# Create differential input between channel 0 and 1

#chan = AnalogIn(ads, ADS.P0, ADS.P1)

print("{:>5}\t{:>5}".format('raw', 'v'))

while True:

readValue = 0

maxValue = 0

for i in range(0,300):

readValue = chan.value

if (readValue > maxValue):

maxValue = readValue

# write the current integer value to a file

f = open("current.txt", "w")

f.write(str(maxValue-6680))

f.close()

print("{:>5}\t{:>5.5f}".format(maxValue-6680, chan.voltage))

time.sleep(0.5)

The file above is essentially the simpletest.py file that Adafruit publish with some amendments.

One of these is that we are only looking at an instantaneous measurement of current. For AC current that could be anywhere along the sine wave in a positive or negative direction.

The solution (which is in the code) is to put in a small loop that determines the maximum value while the loop is running. This indicates the peak value in one direction.

As well as this we can reduce the gain and put in an offset that allows our returned value to read close to zero with no current flowing.

It also includes a small section that writes our current value to a text file. We will use this to contain our value to pass onto Prometheus / Grafana for monitoring later.

Now we can run it using

python current.py

We should see a print out of the values represented by the value of the ADC as an integer and the voltage from the ADC as a floating point value (this is without any current flowing in our sensor).

raw v

-8 0.83203

56 0.82403

40 0.82603

56 0.82803

56 0.82403

56 0.82403

And we should also have a file (called 'current.txt') created and updated with the most recent reading.

/etc/modules file using:sudo nano /etc/modules

i2c-dev

/boot/config.txt file. We can do this using;sudo nano /boot/config.txt

dtparam=i2c_arm=on

sudo apt-get install i2c-tools

sudo reboot

sudo i2cdetect -y 1

If we were using an older B model of Raspberry Pi with 256MB of RAM, we would need to use

sudo i2cdetect -y 0.pi@raspberrypi ~ $ sudo i2cdetect -y 1

0 1 2 3 4 5 6 7 8 9 a b c d e f

00: -- -- -- -- -- -- -- -- -- -- -- -- --

10: -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --

20: -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --

30: -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --

40: -- -- -- -- -- -- -- -- 48 -- -- -- -- -- -- --

50: -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --

60: -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --

70: -- -- -- -- -- -- -- --

python --version

ls /usr/bin/python*

update-alternatives command. First list all available python alternatives;update-alternatives --list python

update-alternatives: error: no alternatives for python

update-alternatives command. For this reason we need to update our alternatives table and include both python 2 and 3. Just check that the numbers for the versions in the commands below match the versions that the previous command indicated were installed.sudo update-alternatives --install /usr/bin/python python /usr/bin/python2.7 1

sudo update-alternatives --install /usr/bin/python python /usr/bin/python3.7 2

highest priority

python --version

sudo apt-get install python3-pip

sudo pip3 install --upgrade setuptools

pip3 install RPI.GPIO adafruit-blinka

sudo pip3 install adafruit-circuitpython-ads1x15

current.py (using nano) with the following contents in the home directory (this code can be downloaded from GitHub here);#!/usr/bin/python

#encoding:utf-8

import time

import board

import busio

import adafruit_ads1x15.ads1015 as ADS

from adafruit_ads1x15.analog_in import AnalogIn

# Create the I2C bus

i2c = busio.I2C(board.SCL, board.SDA)

# Create the ADC object using the I2C bus

ads = ADS.ADS1015(i2c)

ads.gain = 1

# Create single-ended input on channel 0

chan = AnalogIn(ads, ADS.P0)

# Create differential input between channel 0 and 1

#chan = AnalogIn(ads, ADS.P0, ADS.P1)

print("{:>5}\t{:>5}".format('raw', 'v'))

while True:

readValue = 0

maxValue = 0

for i in range(0,300):

readValue = chan.value

if (readValue > maxValue):

maxValue = readValue

# write the current integer value to a file

f = open("current.txt", "w")

f.write(str(maxValue-6680))

f.close()

print("{:>5}\t{:>5.5f}".format(maxValue-6680, chan.voltage))

time.sleep(0.5)

simpletest.py file that Adafruit publish with some amendments.python current.py

raw v

-8 0.83203

56 0.82403

40 0.82603

56 0.82803

56 0.82403

56 0.82403

Create a Service to Run Our Python File

I configured the current measurement as a service as while testing the installation I noticed that the program would occasionally fail at random times. This will allow it to restart if necessary and to start on boot.

The first step in this process is to create a service file which we will call current.service. We will have this in the /etc/systemd/system/ directory.

sudo nano /etc/systemd/system/current.service

Paste the following text into the file and save and exit (the file is also available from GitHub).

[Unit]

Description=Python Current Measurement

After=multi-user.target

[Service]

Restart=on-failure

RestartSec=10s

WorkingDirectory=/home/pi

User=pi

ExecStart=/usr/bin/python /home/pi/current.py

[Install]

WantedBy=multi-user.target

The service file can contain a wide range of configuration information and the case above there is 'Restart' which will restart (duh) the service if it fails and 'ExecStart' which describe where to find python and the current.py executable.

The other important part allows the service to restart if it fails.

Before starting our new service we will need to reload the systemd manager configuration again.

sudo systemctl daemon-reload

Now we can start the current service.

sudo systemctl start current

You shouldn't see any indication at the terminal that things have gone well (or otherwise), so it's a good idea to check current's status as follows;

sudo systemctl status current

We should see a report back that indicates (amongst other things) that 'current' is active and running.

Now we will enable it to start on boot.

sudo systemctl enable current

current.service. We will have this in the /etc/systemd/system/ directory.sudo nano /etc/systemd/system/current.service

[Unit]

Description=Python Current Measurement

After=multi-user.target

[Service]

Restart=on-failure

RestartSec=10s

WorkingDirectory=/home/pi

User=pi

ExecStart=/usr/bin/python /home/pi/current.py

[Install]

WantedBy=multi-user.target

python and the current.py executable.sudo systemctl daemon-reload

sudo systemctl start current

sudo systemctl status current

sudo systemctl enable current

Integrate with Prometheus / Grafana

If you haven't used Prometheus and Grafana for monitoring before, let me take a moment to enthusiastically recommend it to you. Combined, they make a very powerful platform for checking up on your various pieces of IT and they are tools that are widely used in the outside world (in other words, the skills you build in using it are transferable). Better yet, they will run really well on a Raspberry Pi!

I'm not going to describe how to install both here, but I would recommend working your way through this book which you can read online or download (for free) to step through the process.

Assuming you have an instance of Prometheus / Grafana available, we can add a custom exporter for monitoring our current as follows;

We are going to add this instrumentation via the officially supported libraries for Python.

When implemented it will gather our information and expose it via a HTTP endpoint (the same way that Prometheus's node_exporter does with http://<IP Address>:9100/metrics.

Our metric name will reflect the type of thing that is being measured. You can see a range of good examples in the metrics exposed from node_exporter. For example 'cpu_frequency' and 'boot_time'. For our measurements we will have 'current'.

The last part of the name should describe the units being used for the measurement (in plural form). In our case the current will be in 'milliamps'.

The full name of our metrics will therefore be;

- septic_current_milliamps

To use the custom exporter on our target machine (in this case the IP address of the Pi on the septic tank is 10.1.2.210), we’ll need to install the Prometheus client library for Python and pip as follows;

sudo apt-get install python-pip

pip install prometheus_client

To collect information, we need to make sure that we can gather it in a way that will suit our situation.

Our 'current' value is read by a Python script that is running in the background and writing the value to a file called 'current.txt'.

So, our python exporter script (which in this case is named septic-exporter.py) looks like the following (this file is also available from GitHub);

import prometheus_client

import time

UPDATE_PERIOD = 15

current = prometheus_client.Gauge('septic_current_milliamps',

'Value relating to current flow with zero being effectivly nil.')

if __name__ == '__main__':

prometheus_client.start_http_server(9999)

while True:

with open('/home/pi/current.txt', 'r') as f:

current_value = f.readline()

try:

float(current_value)

current.set(float(current_value))

except: pass

time.sleep(UPDATE_PERIOD)

The main actions in our exporter can be summarized by the following entries:

- Import the Prometheus client Python library.

- Declare gauge metric with the metric name that we decided on earlier.

- Instantiate an HTTP server to expose metrics on port 9999.

- Start a measurement loop that will read our metric value every 15 seconds

- Gather our metric value from our text file.

In the same way that we made sure that our current measurement program starts up simply at boot, we will configure our Python exporter script as a service and have it start at boot.

The first step in this process is to create a service file which we will call septic_exporter.service. We will have this in the /etc/systemd/system/ directory.

sudo nano /etc/systemd/system/septic_exporter.service

Paste the following text into the file and save and exit (this file is also available at GitHub).

[Unit]

Description=Septic Exporter

After=multi-user.target

[Service]

User=pi

ExecStart=/usr/bin/python /home/pi/septic-exporter.py

[Install]

WantedBy=multi-user.target

The service file can contain a wide range of configuration information and in our case there are only a few details. The most interesting being the 'ExecStart' details which describe where to find python and the septic-exporter.py executable.

Before starting our new service we will need to reload the systemd manager configuration again.

sudo systemctl daemon-reload

Now we can start the septic_exporter service.

sudo systemctl start septic_exporter

You shouldn't see any indication at the terminal that things have gone well, so it's a good idea to check septic_exporter's status as follows;

sudo systemctl status septic_exporter

We should see a report back that indicates (amongst other things) that septic_exporter is active and running.

Now we will enable it to start on boot.

sudo systemctl enable septic_exporter

The exporter is now working and listening on the port:9999

To test the proper functioning of this service, use a browser with the url of our current measuring Pi: http://10.1.2.210:9999/metrics

This should return a lot lot statistics. Some of them will look a little like this;

# HELP septic_current_milliamps Value relating to current flow with zero being effectivly nil.

# TYPE septic_current_milliamps gauge

septic_current_milliamps -520.0

There are a lot more metrics than just our septic info, but you can see our metrics there.

Now that we have a computer exporting metrics, we will want it to be gathered by Prometheus

node_exporter does with http://<IP Address>:9100/metrics.node_exporter. For example 'cpu_frequency' and 'boot_time'. For our measurements we will have 'current'.10.1.2.210), we’ll need to install the Prometheus client library for Python and pip as follows;sudo apt-get install python-pip

pip install prometheus_client

septic-exporter.py) looks like the following (this file is also available from GitHub);import prometheus_client

import time

UPDATE_PERIOD = 15

current = prometheus_client.Gauge('septic_current_milliamps',

'Value relating to current flow with zero being effectivly nil.')

if __name__ == '__main__':

prometheus_client.start_http_server(9999)

while True:

with open('/home/pi/current.txt', 'r') as f:

current_value = f.readline()

try:

float(current_value)

current.set(float(current_value))

except: pass

time.sleep(UPDATE_PERIOD)

septic_exporter.service. We will have this in the /etc/systemd/system/ directory.sudo nano /etc/systemd/system/septic_exporter.service

[Unit]

Description=Septic Exporter

After=multi-user.target

[Service]

User=pi

ExecStart=/usr/bin/python /home/pi/septic-exporter.py

[Install]

WantedBy=multi-user.target

python and the septic-exporter.py executable.sudo systemctl daemon-reload

sudo systemctl start septic_exporter

sudo systemctl status septic_exporter

sudo systemctl enable septic_exporter

# HELP septic_current_milliamps Value relating to current flow with zero being effectivly nil.

# TYPE septic_current_milliamps gauge

septic_current_milliamps -520.0

Adding adding our custom exporter to Prometheus

We need to add the IP address of our new metrics source to the Prometheus prometheus.yml file. To do this we can simply add the IP address of a node that is running the septic_exporter as a new target and we are good to go.

On our Prometheus server;

nano /home/pi/prometheus/prometheus.yml

At the end of the file add the IP address of our new node - targets: ['10.1.2.210:9999'];

scrape_configs:

# The job name is added as a label `job=<job_name>`

# to any timeseries scraped from this config.

- job_name: 'prometheus'

# metrics_path defaults to '/metrics'

# scheme defaults to 'http'.

static_configs:

- targets: ['localhost:9090']

- targets: ['10.1.1.109:9100']

- targets: ['10.1.2.210:9999']

Then we restart Prometheus to load our new configuration;

sudo systemctl restart prometheus

Now if we return to our Prometheus GUI to check which targets we are scraping we can see our new node at 10.1.2.210.

prometheus.yml file. To do this we can simply add the IP address of a node that is running the septic_exporter as a new target and we are good to go.nano /home/pi/prometheus/prometheus.yml

- targets: ['10.1.2.210:9999'];scrape_configs:

# The job name is added as a label `job=<job_name>`

# to any timeseries scraped from this config.

- job_name: 'prometheus'

# metrics_path defaults to '/metrics'

# scheme defaults to 'http'.

static_configs:

- targets: ['localhost:9090']

- targets: ['10.1.1.109:9100']

- targets: ['10.1.2.210:9999']

sudo systemctl restart prometheus

A huge thank you for documenting this. A treasure trove of information :)

ReplyDeleteThe pumps in septic tanks are usually low-tech and controlled by float switches in the tanks - so you have to detect the current flow, not the voltage supplied to them. Capturing time-series data and knowing when the pumps are switching on/off, and thus the run duration, provides data which you can use to gauge distribution field and dripline health etc.

The frequency of pump runs can be used to determine flow (litres per hour/day etc) because you will be able to calculate how many litres are moved per run (irrespective of how long that takes). Use the difference in float height between on/off events and the circumference of the tank to calculate volume moved.

I'm glad it was useful. I've looked at a few options to better understand and monitor what is going on in the system. This has included a flow meter on the outlet (for exactly the points that you make above) and a pressure switch to determine if the aeration pump is providing the correct pressure. One of the more interesting thoughts I've entertained is to add a vibration sensor to the aeration pump which should be able to determine if a valve is failing.

Delete